- Home

- Examples

Cooperation time: 2017

Client: Guangdong Dongguan Zhaoying Building Material Co., Ltd.

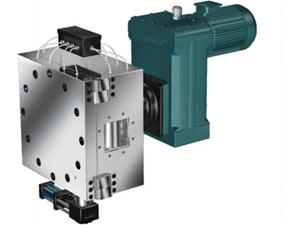

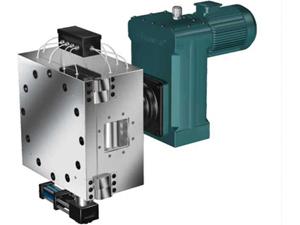

Requirements: their previous filter system was energy-intensive and expensive. An automatic self-cleaning screen was required to cooperate with their current production equipment aimed at decreasing energy consumption and production cost.

Cooperation time: 2016

Client: Shanghai Jixiang Building Materials Group

Requirements: the production cost of the previous granulator production line was too high. A new automatic self-cleaning screen is required to match the extrusion system, cut down the manufacturing costs and improve the market competitiveness.

Cooperation time: 2018

Client: Jiangxi Haoxing General Aviation Technology co., Ltd.

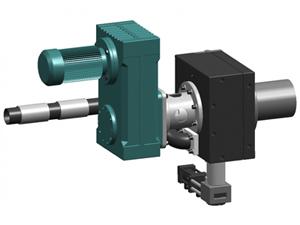

Requirements: a high-performance filter system was required to match their granule and sheet extrusion production line. The new melt filtration system should lower the requirements of the raw material grade, reduce the manufacturing cost and improve competitiveness of the production line.

Cooperation time: 2013

Client: Zhejiang Yongsheng Plastic Industry Co., Ltd.

Requirements: Yongsheng is a plastic recycling company and used to utilize a traditional screen changer, which had high energy consumption, required high labor intensity and polluted the environment. A new continuous cleaning melt filter, aimed at solving these problems, was required to configure their equipment.