- Home

- Products

In the plastic granulation and extrusion industry, the melt filter plays a vital role in the operation of plastic extruders. Selecting the proper melt filtration system for will help you establish a high-quality contaminated plastic recycling line. We have created a new generation ultra-fine micro perforation design for use in continuous melt filters to replace screen changers. This high performance melt extruder is suitable for continuous contaminant discharge and features excellent throughput even under high degrees of contamination. Typically, the appropriate filter is selected in consultation with the customer depending on the application details. LEENY’s melt filters can be installed in a wide range of extrusion equipment, such as plastic granulators, aluminum-plastic panel extruders, XPS extruders, film faced plywood extruding machines, etc. One of the most significant advantages of our products is that there is no need to replace the extruder screens, ensuring 24-hour continuous operation, maximizing production efficiency and reducing operating costs.

-

- Continuous Melt FilterWe design and manufacture high quality continuous melt filters for twin or single screw extruders in the plastic recycling industry. The melt-filtration system is suitable for processing recycled polypropylene (PP), polyethylene (PE).polyethylene terephthalate (PET) and polylactic acid (PLA).

-

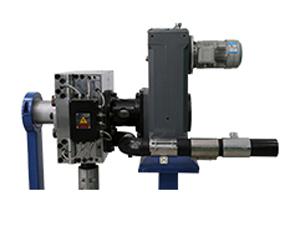

- Automatic Melt FilterThe automatic melt filter lets the melt flow unhindered in the plastic recycling extrusion process. Compared to conventional screen chargers, the melt extruder filter means you do not need to replace the screen repeatedly and greatly reduces the labor intensity.

-

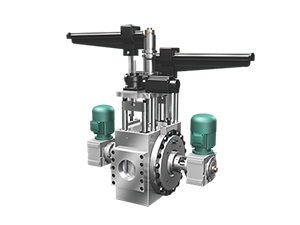

- Double Piston Continuous Melt FilterThe double piston continuous melt filter features a highly cost-effective and boosted throughput rate of plastic recycling materials. In the past, people relied on screen changers or even conventional mesh filters to remove the contaminants from extruders. Nowadays, using our new generation melt filter means that you no longer need to replace the filter screen.

-

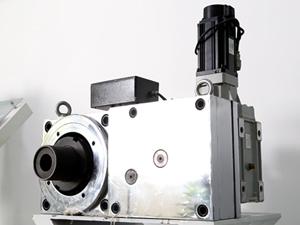

- Automatic Filter ChangerThe microdrilled continuous melt filter is appropriate for extrusion systems that have higher filtration precision requirements and better raw materials. The microdrilled melt filtration system can produce the most superior finished filtration products. The mesh size varies from 50 to 100.

-

- Continuous screen changerThe continuous melt filtration screen changer will automatically control the servo motor to automatically rotate, exhaust, and feed. Continuous production is possible without turning off the machine to change the screen, thus avoiding down time, and improves the production efficiency.

-

- Hydraulic Screen ChangerThe hydraulic screen changer is a filter system used for handling new materials or recycling materials. A conventional melt filter requires that a machine be shut down to change the screen, which influences the filtration quality.

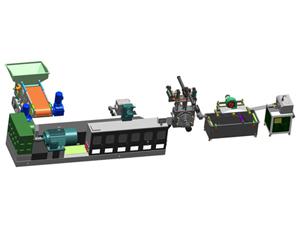

The granule extruder is used for plastic recycling and granulation, and is capable of handling PP, PE, PVC and any other plastics, as well as films with water, woven bags, and jumbo bags. We also offer customized filtration equipment according to customer needs, and a full production line consists of a feeding device, granulator, filter, cooling device, and control system. The granule extruder line will be debugged before delivery, and our technicians will provide onsite installation, debugging and training for customers.

-

- Plastic Recycling Line, Pelletizing Extrusion LineThe granule extruder is used for plastic recycling and granulation, and is capable of handling PP, PE, PVC and any other plastics, as well as films with water, woven bags, and jumbo bags.